Small gasket big responsibility

Small gasket, seemingly insignificant, but carrying a great responsibility.

Small gasket, seemingly insignificant, but carrying a great responsibility.

Quality is life, integrity is the soul

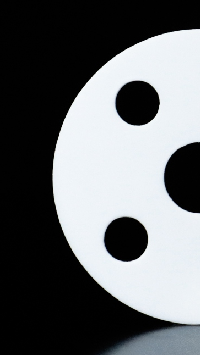

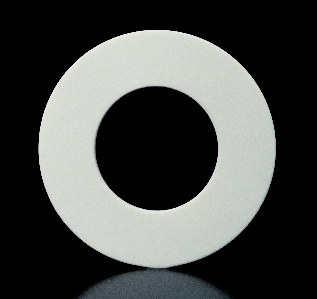

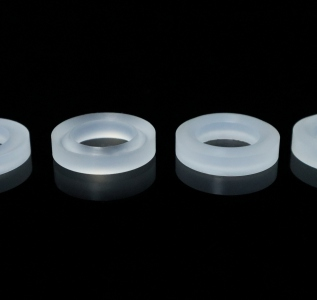

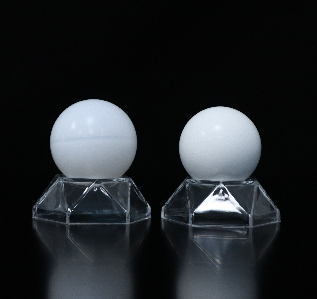

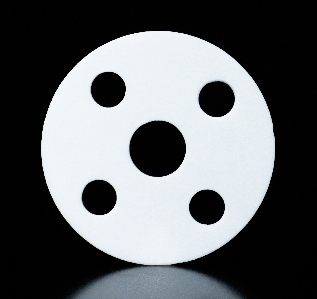

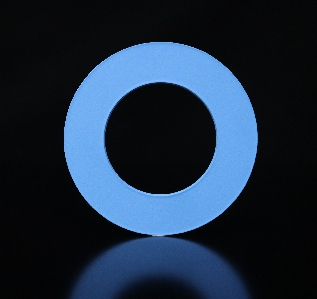

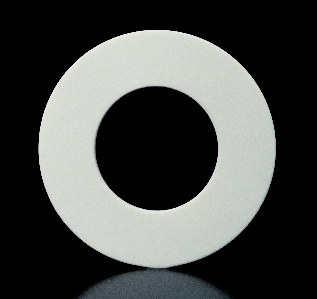

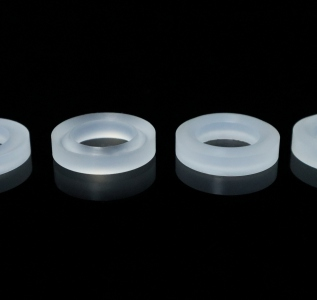

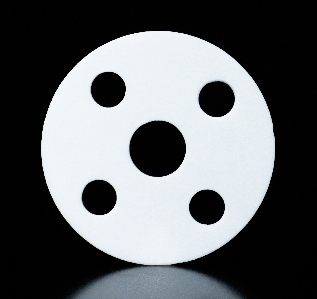

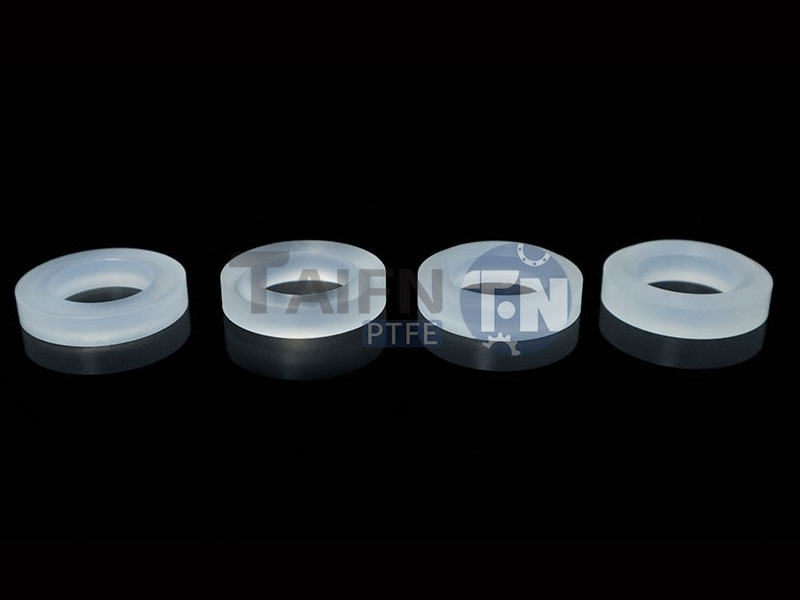

Ptfe gaskets are divided into molded gaskets and turning gaskets according to different processes. PTFE gasket has good aging resistance, very low friction coefficient, high temperature resistance and strong corrosion resistance. As a sealing element, it can be used in various equipment and pipe flange joints in the chemical industry, petrochemical, biomedical and so on. The operating temperature range is -180 to +200 degrees.

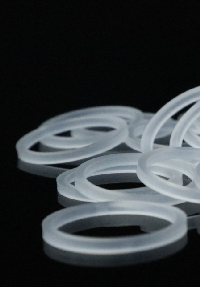

Expanded polytetrafluoroethylene gasket (EPTFE),EPTFE has the chemical stability of tetrafluoroethylene, while its multi-fiber structure makes it as a sealing product with unimaginable toughness, more importantly, it fundamentally solves the common problems of other types of tetrafluoroethylene sealing materials – creep and cold flow, and the performance is greatly improved compared with pure tetrafluoroethylene gasket and filled tetrafluoroethylene gasket.

The polytetrafluoroethylene coated gasket is a non-metallic gasket, generally composed of two parts: a coating layer and an insert. The coating layer mainly plays the role of corrosion resistance, usually made of polytetrafluoroethylene material, the insert (filler) is A non-metallic sealing material with or without a metal reinforcement layer, usually non-asbestos gasket, rubber gasket, flexible graphite gasket, etc., according to the inner core structure is different, divided into A type (V, Y), B type and C type.

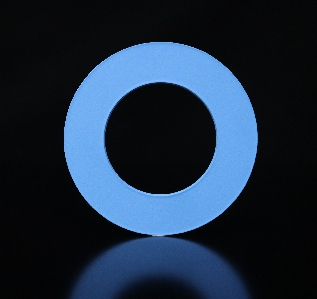

Modified tetrafluoroethylene gasket (RPTFE) is made of polytetrafluoroethylene resin to add a certain amount of filler, such as glass fiber, carbon fiber, graphite, molybdenum disulfide, bronze powder, etc., after high-speed mixing and molding, and then made of high temperature sintering. Excellent compressibility, recovery and sealing properties. Its unique properties and advanced characteristics show sealing and torque retention, in terms of cold flow and creep characteristics of the material, overcoming the shortcomings of traditional PTFE, while it can hold the bolt load better than traditional PTFE, which both improves the durability of the seal and reduces the maintenance of the flange.

Adequate stock is like a solid backing, giving people peace of mind and ensuring a continuous supply.

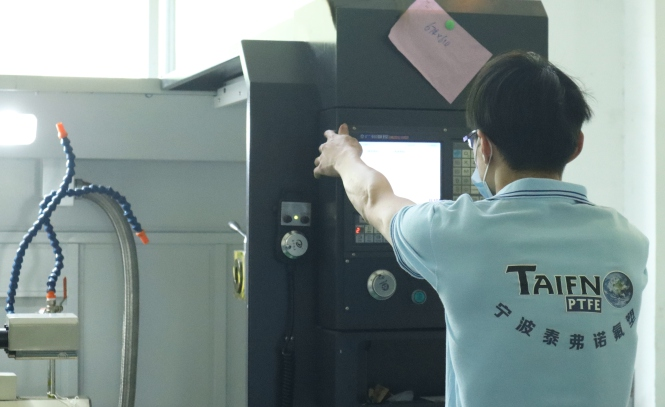

Professional testing equipment, with excellent performance and high reliability, provides a strong help for quality control and problem solving in various fields.

Comprehensive MES system, data collection, process monitoring, quality control, resource scheduling and other functions in one

Be able to adjust to different needs at any time to ensure that the product or service is delivered to you at the most suitable time.

A professional technology research and development team, with excellent wisdom and superb skills, constantly forge ahead and inject strong impetus into the development of the industry.

It means that the enterprise has the guarantee of efficient operation, from raw material procurement to product delivery, every link is like a precision gear, laying a solid foundation for the sustainable development of the enterprise and excellent quality.

More than customized parts processing services, very professional processing advice and after-sales technical guidance support are our advantages.

Our technical team is experienced in seal design and construction, and Teflon can provide you with the right advice on the design of high quality PTFE and other fluoropolymer products to reduce costs; When reviewing drawings and quotations, we will give the best machining plan according to the material characteristics; In case of cold creep flow of PTFE material affecting the processing, need to adjust the shape or tolerance of the part, we will use professional knowledge and experience to discuss the improvement suggestions and methods with you.

From raw materials, incoming materials mixing and filling, production, processing to finished products, Teverno staff records every step of the process, ensuring that the production process is fully identifiable and traceable.